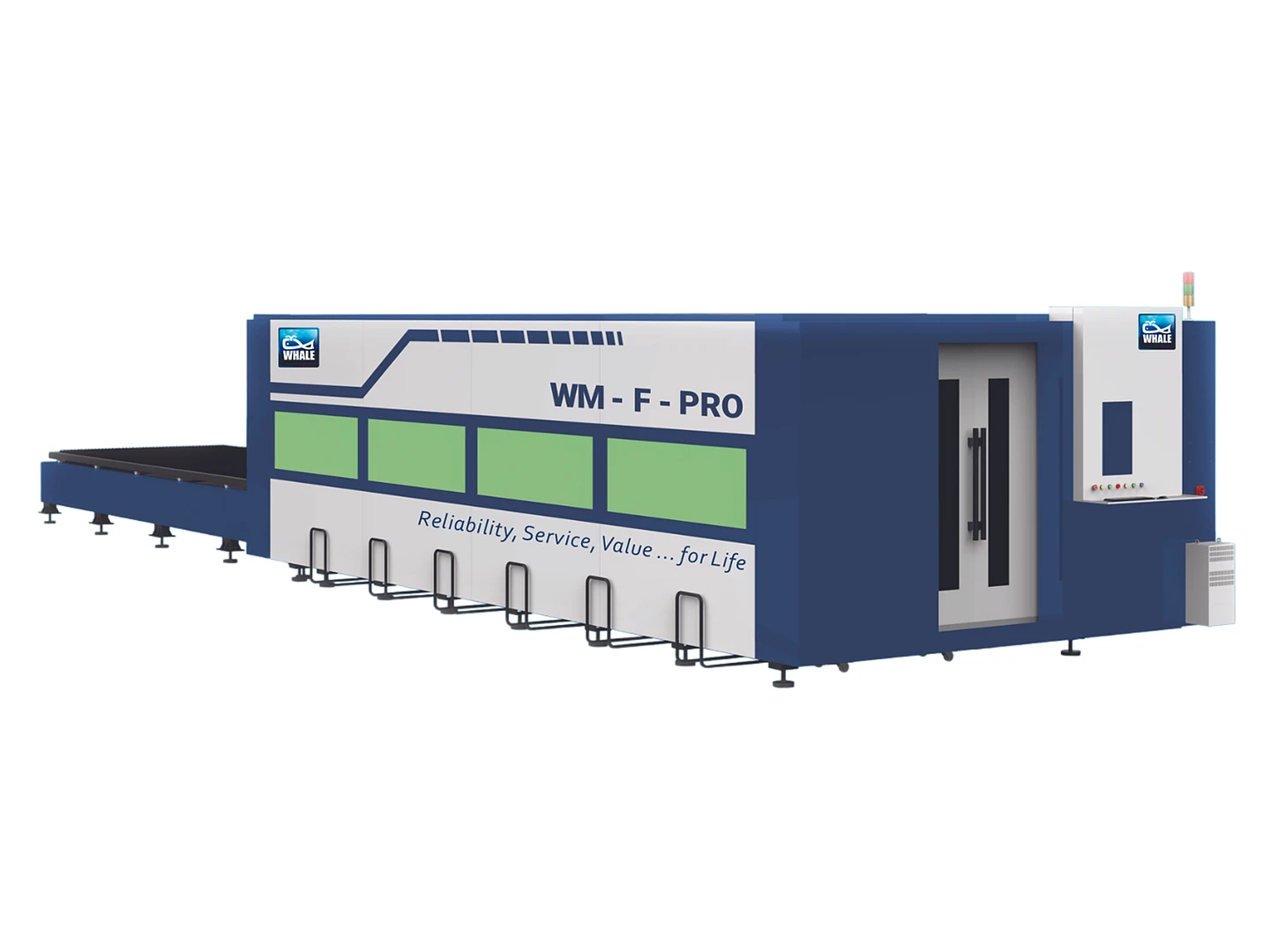

WM Series - F-Pro is Whale Machineries baseline laser cutting machine designed to provide the best value for price in the market. Whale Machineries is popular for intervening in the industry with pioneering innovations and this laser system provides excellent cutting quality as well as superior productivity. With its relentless attributes, it is turning out to be the favorite of fabricators.

WM Series - F-Pro is a product of Whale Machineries trademark Fiber Laser cutting series which stands tall in reliability, efficiency and productivity. It is designed for manufacturers and fabricators ready to start with Laser cutting technology and expecting productivity at an affordable price and minimum lead time for supply made to order.