- Mon - Sat: 9:00 - 19:00

- +91 74186 97778

Hydraulic Servo CNC Press Brake

The machine’s overall welding, overall processing structure, and the main parts of machine are all analysed by ANSYS finite element analysis software, which has ensured the reliability of machine and the precision of entire machine

The CNC control system adopts Netherland DELEM, Italian ESA, or Swiss CYBELEC products, which can achieve the functions of graphic programming for bending angle, compensation for angle amendment, automatic calculation also adjustment of bending pressure, automatic calculation of compensation for workbench distortion, extending length of workpieces, bending pressure for buttom bending, open distance, and automatic withdrawal of rear stopper, etc.

Pump Control Servo CNC Brake

- The system consumes less energy since servo motor used.

- Oil distribution according to needs so restriction loss also saves energy.

- Since temperature raise is reduced it results in stability and increase in the working life of the hydraulic press system and oil cylinder.

- The gear pump system offers advantages in terms of noise reduction, maintenance efficiency, and positional accuracy when compared to the more complex proportional valve control systems.The ram repositioning precision is stated as +0.01mm, with the highest achievable precision being +0.05mm.

- Possible to reduce the consumption of hydraulic oil up to 70%.

- On simplifying the installation method, a system can streamline the setup process, reduce costs, and minimize errors, leading to overall greater efficiency in both the short and long term.

- Flexible installation meets required needs.

- Better economic and higher performance-to-price ratio.

D-SVP

- Province: Save 60% of electricity consumption compared with traditional transmissions

- High: Work efficiency could increase by 30% due to reduce of cycle time

- Quasi: The positioning accuracy is achievable up to 5um

- Quiet: Due to less noise the machine tool works comparatively quiet

- Less: The amount of hydraulic oil used about 30% of the traditional

- Easy: Machine tools are easier to manufacture, easier to maintain, and have a lower failure rate.

HOERBIGER ePrAX Control

- The system offers high efficiency, significant energy savings, and operational cost reductions while maintaining or improving performance, reduction in duty cycle up to 10%, making it highly beneficial in industrial and commercial applications with predominate design reduction of Oil Tank capacity over all to 70%

- On Compared with the traditional system, energy efficiency 50% more

- The positioning accuracy of precision-up to 5um integrated servo pump

- Integrated pressure filters ensure Less-noise at work, high stability and long service life.

Machine Selection by Length, Thickness and Tonnage

“Click me”

TECHNICAL PARAMETERS

| Model | Nominal Pressure (kN) | Length of Table(mm) | Distance between columns (mm) | Throat Depth (mm) | Stroke (mm) | Open Height (mm) | Main Motor (kW) | Overall Dimensions LxWxH (mm) |

|---|---|---|---|---|---|---|---|---|

| 40T/1300 | 400 | 1300 | 1120 | 250 | 150 | 460 | 5.5 | 2000*1500*2350 |

| 63T/1600 | 630 | 1600 | 1300 | 300 | 150 | 460 | 5.5 | 2300*1600*2500 |

| 63T/2500 | 630 | 2500 | 2050 | 300 | 150 | 460 | 5.5 | 3100*1600*2500 |

| 80T/2500 | 800 | 2500 | 2050 | 300 | 150 | 460 | 7.5 | 3100*1600*2600 |

| 100T/3200 | 1000 | 3200 | 2700 | 400 | 200 | 490 | 11 | 3800*1800*2600 |

| 100T/4000 | 1000 | 4000 | 3100 | 400 | 200 | 490 | 11 | 4600*1800*2600 |

| 125T/3200 | 1250 | 3200 | 2700 | 400 | 200 | 490 | 11 | 3800*1800*2700 |

| 125T/4000 | 1250 | 4000 | 3100 | 400 | 200 | 490 | 11 | 4600*1800*2700 |

| 160T/3200 | 1600 | 3200 | 2700 | 450 | 200 | 490 | 15 | 3800*2000*3100 |

| 160T/4000 | 1600 | 4000 | 3100 | 450 | 200 | 490 | 15 | 4600*2000*2800 |

| 220T/3200 | 2200 | 3200 | 2600 | 450 | 200 | 490 | 18.5 | 3800*2200*2850 |

| 220T/4000 | 2200 | 4000 | 3100 | 450 | 200 | 490 | 18.5 | 4600*2200*2850 |

| 250T/3200 | 2500 | 3200 | 2600 | 450 | 250 | 540 | 22 | 3800*2000*2900 |

| 250T/4000 | 2500 | 4000 | 3100 | 450 | 250 | 540 | 22 | 4600*2100*3100 |

| 250T/5000 | 2500 | 5000 | 3800 | 450 | 250 | 540 | 22 | 5600*2150*3150 |

| 250T/6000 | 2500 | 6000 | 4600 | 450 | 250 | 540 | 22 | 6600*2150*3150 |

| 300T/3200 | 3000 | 3200 | 2610 | 500 | 250 | 580 | 22 | 3800*2250*3200 |

| 300T/4000 | 3000 | 4000 | 2820 | 500 | 250 | 580 | 22 | 4600*2500*3400 |

| 300T/5000 | 3000 | 5000 | 3800 | 500 | 250 | 580 | 22 | 5600*2500*3400 |

| 300T/6000 | 3000 | 6000 | 4600 | 500 | 250 | 580 | 22 | 6600*2500*3400 |

| 400T/3200 | 4000 | 3200 | 2400 | 500 | 250 | 580 | 30 | 3800*2700*3500 |

| 400T/4000 | 4000 | 4000 | 3200 | 500 | 250 | 580 | 30 | 4600*2700*3500 |

| 400T/5000 | 4000 | 5000 | 3800 | 500 | 250 | 580 | 30 | 5600*2700*3500 |

| 400T/6000 | 4000 | 6000 | 4600 | 500 | 250 | 580 | 30 | 6600*2700*3500 |

| 500T/4000 | 5000 | 4000 | 3100 | 500 | 300 | 600 | 37 | 4600*2700*3500 |

| 500T/5000 | 5000 | 5000 | 3800 | 500 | 300 | 600 | 37 | 5600*2700*3500 |

| 500T/6000 | 5000 | 6000 | 5050 | 500 | 300 | 600 | 37 | 6600*2700*3600 |

| 600T/5000 | 6000 | 5000 | 3800 | 600 | 320 | 640 | 45 | 5600*3300*3900 |

| 600T/6000 | 6000 | 6000 | 5050 | 600 | 320 | 640 | 45 | 6600*3300*3900 |

| 600T/7000 | 6000 | 7000 | 5300 | 600 | 320 | 640 | 45 | 7600*3300*3900 |

| 700T/6000 | 7000 | 6000 | 4900 | 600 | 320 | 700 | 55 | 6600*3500*4000 |

| 800T/6000 | 8000 | 6000 | 4600 | 600 | 320 | 800 | 30*2 | 6600*3500*4000 |

MODEL & SPECIFICATIONS

| Delem | DA-53T | DA-58T | DA-66T | DA-69T |

|---|---|---|---|---|

| Screen parameters | 10.1" Multi-point Touch Screen | 15" Multi-touch Screen | 17" Infrared Touch Screen | 17" Infrared Touch Screen |

| Programming mode | Manual programming | Manual Programming and 2D Graphic Programming | 2D Graphic Programming and 3D Graphic Display | 3D Graphics Programming and 3D Graphics Display |

| Fast clamping function of mould | Non support | Non support | Support | Support |

| Networking settings | No | Optional | Complete Windows Application Package | Complete Windows Application Package |

| Number of control axes | Up to 4+1 Axis Control | Up to 4+1 Axis Control | Controllable 8+1 axis and above | Controllable 8+1 axis and above |

| Angle detection | No | No | Sensor interface with angle detection | Sensor interface with angle detection |

| Compatibility | No | No | DELEM-compatible modular structure | DELEM-compatible modular structure |

| Panel personalization | Panel cannot be personalized | Panel cannot be personalized | OEM panels can be personalized | OEM panels can be personalized |

| Offline software | Support offline software, USB interface can use anyU disk and specified code | Support offline software, USB interface can use any U disk and specified code | Support offline software, USB interface needs to use randomly configured designated U disk | Support offline software, USB interface needs to use randomly configured designated U disk |

DELEM DA53T Control System

DELEM DA 58T 2D CNC Control Unit

DELEM DA 66T 2D CNC Control Unit

DELEM DA 69T 3D CNC Control Unit

CYBELEC CybTouch8 PS CNC Control Unit

CYBELEC CybTouch12 PS 2D CNC Control Unit

MF53S control system for CNC bending machine

CORE CONFIGURATION

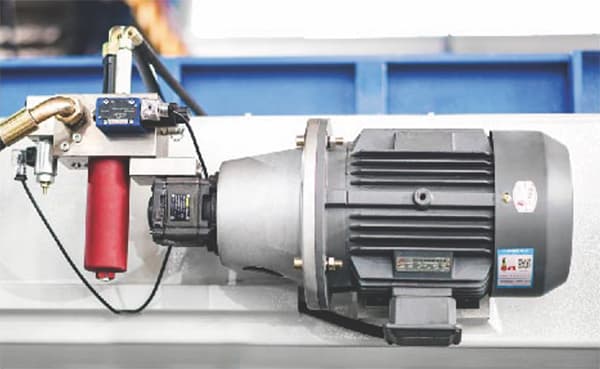

Oil Pump Motor (Optional)

Uses three phase asynchronous motor and large flow pump as hydraulic active power source.

Servo Motor (Optional)

Using servo motor as the main power source of hydraulic pump can save about 40% energy.

The overall efficiency of the slider increases by about 7-20%.

Oil temperature can be reduced by about 10-20 °C.

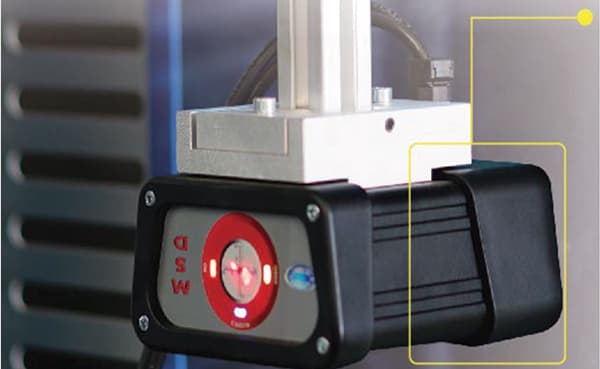

Safety System (Optional)

Provide comprehensive protection for the operator in the place close to the workpiece.

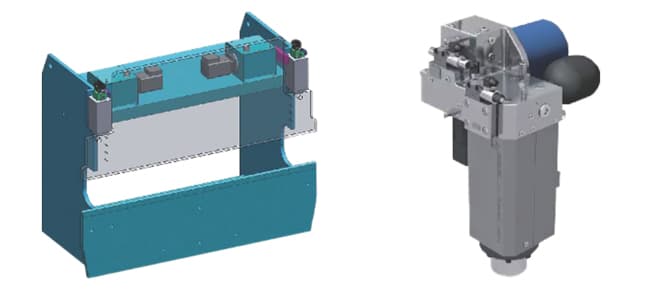

Mechanical Compensation

By CNC control system, precise compensation is obtained to ensure high quality bending accuracy

Grating Ruler

Exact measured distortion and feedback compensation, to ensure the precision of the bending, effectively prevent non-standard workpiece collision linear scales.

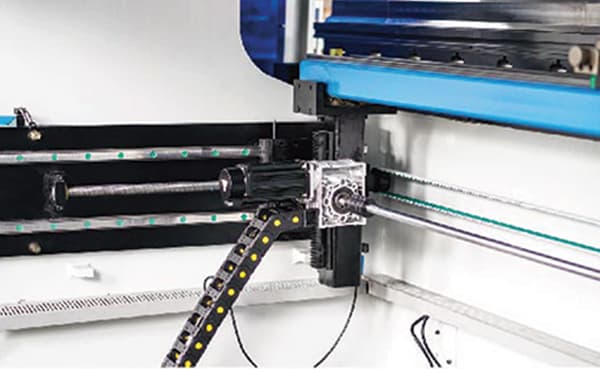

Precise back gauge system for faster and more accurate positioning

Steel structure welding, high rigidity, servo motor, ball screw, linear guide drive, ensure the accurate positioning of the workpiece.